Wearables integration techniques

No one-solution-fits-all

Wearables designers nowadays have access to a broad range of electronics and textiles integration techniques, thanks to technological advances such as miniaturisation, the development of smart textiles, conductive yarns, stretchable electronics, and improved overmoulding and 3D printing techniques, among others.

Besides the different types of haptic activators (vibration motors) described in Haptic feedback wearables, many other factors influence what type of integration technique is most suitable for your wearable.

Interested in learning more about integration techniques?

At Elitac Wearables, our hardware and software specialists and designers have over 45 years’ combined experience developing wearables. Because we believe there is not (yet) one integration technique that works for each and every wearable, we have researched, tested, and mastered the majority of effective integration techniques, including:

- Printed

- Laminated

- Flexible

- Stretchable

- Smart textiles

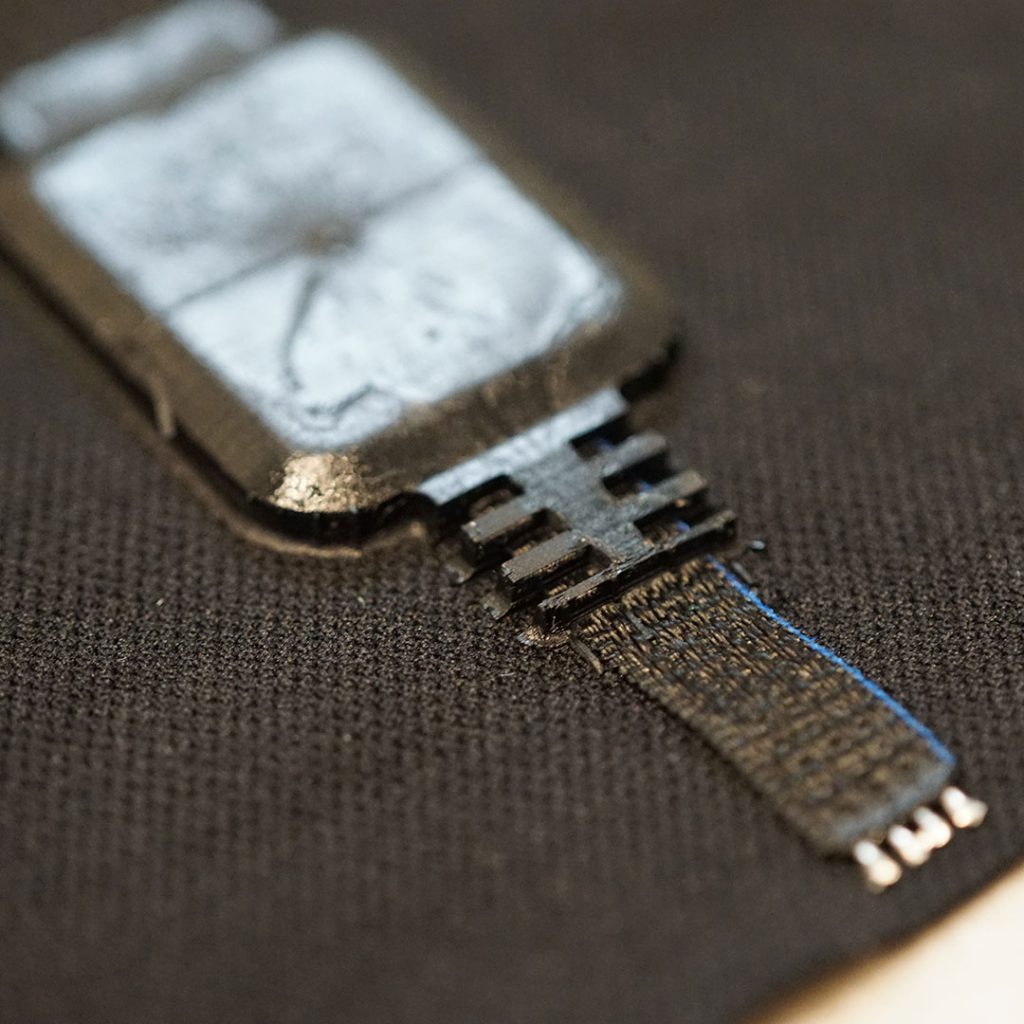

- Conductive yarns (sewn, embroidered, knitted, woven)

- Conductive stretchable tapes

- Conventional (wired)

More importantly, we can prototype, apply, and produce most of them in our in-house Wearables Lab.

Electronics & textiles: Degree of integration

Integration can range on a scale from:

How do we decide which integration technique to use?

In our experience, there is no one integration technique suitable for each and every wearable (yet). Instead, the optimum technique depends on how the wearable will be used, by whom, where, etc. In addition, the cost price and number of products that will be produced can also influence the selection of integration technique.

When we start a new project, we discuss each of the factors below with our clients to get a clear idea of the requirements. Based on these, we can advise clients on the (dis)advantages of each technique, and help them select the optimum one for their wearable.

Type of users

Will they be new users each time, or recurrent users? Will they have time to prepare and develop operator knowledge, or does it need to be ‘plug and play’? How many sizes are required?

Context

In what situations will the wearable be used? Inside, outside? Active, stationary? In extreme conditions?

Type of use

Will it be worn for longer periods of time? Will the wearer be moving around a lot? Are we looking at a high-power application? Or low-noise requirements?

Body placement

Will the wearable be worn on active body parts such as the legs and arms, or more static ones like the waist, torso or back? The location of the wearable or its electronic components can influence durability, size, power, flexibility, etc.

Business case

What is the target cost price for the wearable?

Washability

Does the wearable need to be washable in its entirety, how often and at which temperatures?

Life-span

What are the expectations in terms of durability?

Quantity

How many pieces will we produce?

Sustainability

Should the wearable (or its components) to be completely recyclable (and therefore e.g. separable)?

Social acceptability

Would users prefer the wearable to be as inconspicuous as possible, to avoid drawing extra attention to a medical condition? Or on the contrary, should it be intentionally visible?

Contact us

If you have any questions about integration techniques, and which we would recommend for your wearable, please don’t hesitate to contact us: