Softgoods Development

& Production

Softgoods

Developing wearables means combining hard and soft materials. At Elitac wearables we have the expertise to choose the right materials and constructions for the job. Our team of product, textile and softgoods designers bring a variety of experiences to the table, ranging from fashion, backpacks, footwear, sports equipment, consumer electronics, and more.

Through all this experience, and 10 years of developing wearables, we have a strong network of material suppliers and manufactures to realise these often niche requirements and capabilities.

At Elitac Wearables, we have over 45 years’ combined experience developing wearables, integrating electronics into textiles, to wear them close to the body. We protect the electronics, while making sure the wearable is functional, comfortable, and in some cases even washable. Have a look at our projects like the Mission Navigation Belt, BalanceBelt, SmartShoulder, and see what we can do for your development.

Why combine different materials?

Some products require combining different materials. The biggest reason in the market of wearables, is because the product (wearable) is worn close to the body. The product is worn during many different activities, like sports, sleep, rehabilitation, daily life, etc. These different use cases lead to very different requirements, ranging from washability, support, breathability, cooling, bio-compatibility, durability, and many, many more.

But they have one thing in common in one way or another: they need to be comfortable, which often implies they need to be soft. By being soft, flexible and sometimes even elastic, wearables can form around the body in a natural way. And they avoid pressure points or even puncture.

Why make it so hard?

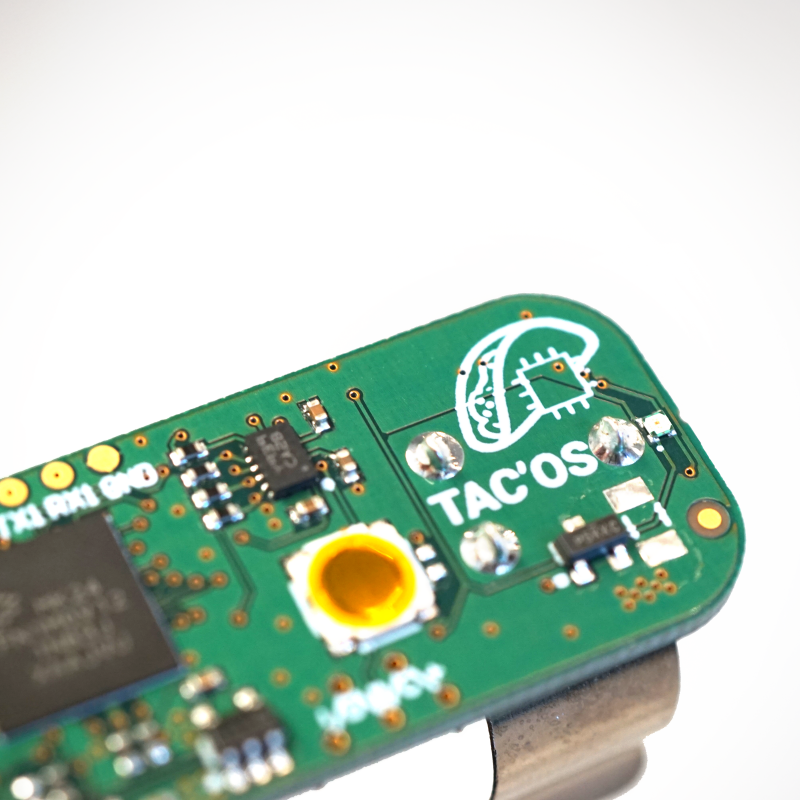

On the other hand, we need hard(er) materials, like rubbers and plastics, to protect our delicate and often expensive hardware (electronics) and some functional parts often depend on their rigid, mechanical properties, like buckles, snaps, sliders, housings and more.

Especially when batteries are involved (as with almost every product nowadays), these need to be protected not only from being punctured, but even from bending. If they’re not, they could heat up or even explode!

Also, hard and rigid materials often are easier to waterproof a design, protecting electric circuits from getting harmed by water creeping in.

Production

Which brings us to the manufacturing of softgoods products. As you can imagine, producing hard plastics, by using injection moulding, screwing, glueing, welding, etc., is done in completely different production facilities than producing and handling textiles.

And even in the textile industry, the manufacturers have specialised in specific niches, meaning you need a different manufacturer for let’s say stretch materials than for non-stretch materials, because you need different machines, needles, tools, etc. to be able to handle them.

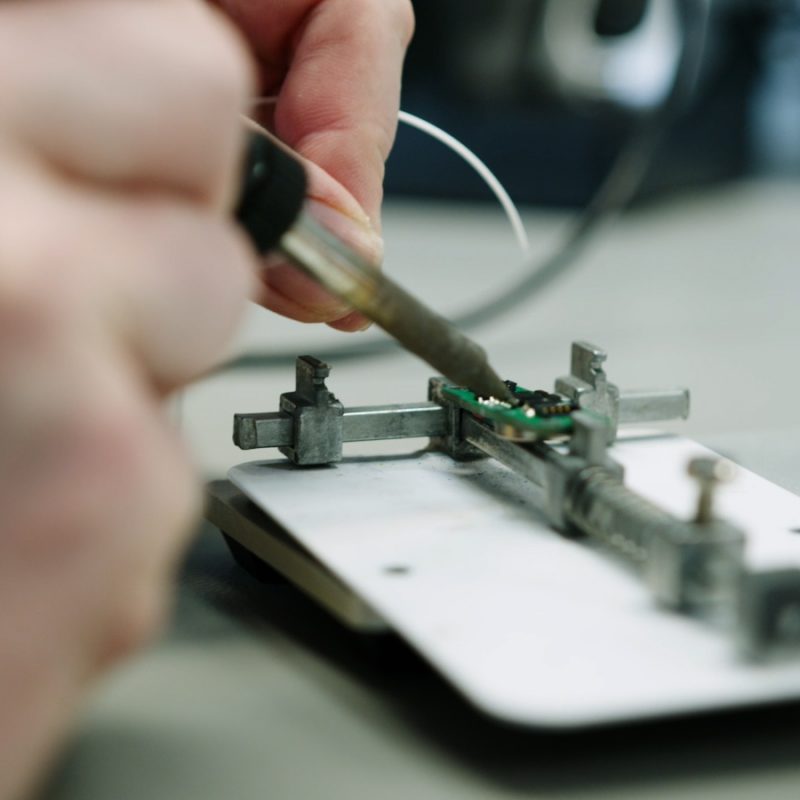

And as most textile manufacturers are not used to handle hard parts, they certainly are not equipped to handle electronic components, which requires a totally different production setup and tooling!

Fortunately, through the years we have found these niche companies that do have this experience and the capability to work with hard and soft parts, even electronics both in Europe as well as in Asia. But more important: they are willing to handle it!

Contact us

Contact us to find out how we can help you to develop your wearable softgoods product, or how we can get your softgoods into production.