Haptic feedback wearables

More than just vibration motors

To develop truly effective haptic feedback wearables, one must consider more than just the hardware. It is a delicate balance between hardware, software, integration methods, human factors, vibration patterns, constellations and more. At Elitac Wearables, we specialise in all these facets of haptic wearables development.

We can advise you on the most (cost-)effective way to apply haptic feedback in your wearable: we start by evaluating your requirements, the end users’ needs, the application and budget. Then, we take you step by step through the process of optimising the haptic feedback for your wearable.

The benefits of haptic feedback in wearables

Reduced sensory overload

By addressing the underutilised sense of touch, the eyes and ears (vision and sight) remain free for other tasks.

Directional information

Research has shown that haptic feedback wearables are very effective at indicating directional information from a user-centred point of view, especially when the event is rare or unexpected.

Sensory replacement and augmentation

Wearable haptic devices can replace or augment (partially) impaired senses for a variety of applications.

Haptic feedback offers benefits both in the case of medical impairments (impaired vision, balance organs, etc.) and situational impairments (lack of real-time visual feedback during microscopic and keyhole surgery).

Intuitive

Haptic feedback has proven to be very intuitive, especially for navigation or directional purposes, even in 3D (distance).

It requires minimal training, and short, simple tactile messages can be processed quickly by the user.

Effective risk communication

Combining visual and tactile information can be more effective than visual information alone in the communication of risks.

Distinct

A haptic feedback wearable can always be felt: In the case of auditory and visual overload, users are still aware of “the tap on the shoulder”. This greatly reduces the likelihood that vital information is missed.

Our experience and expertise

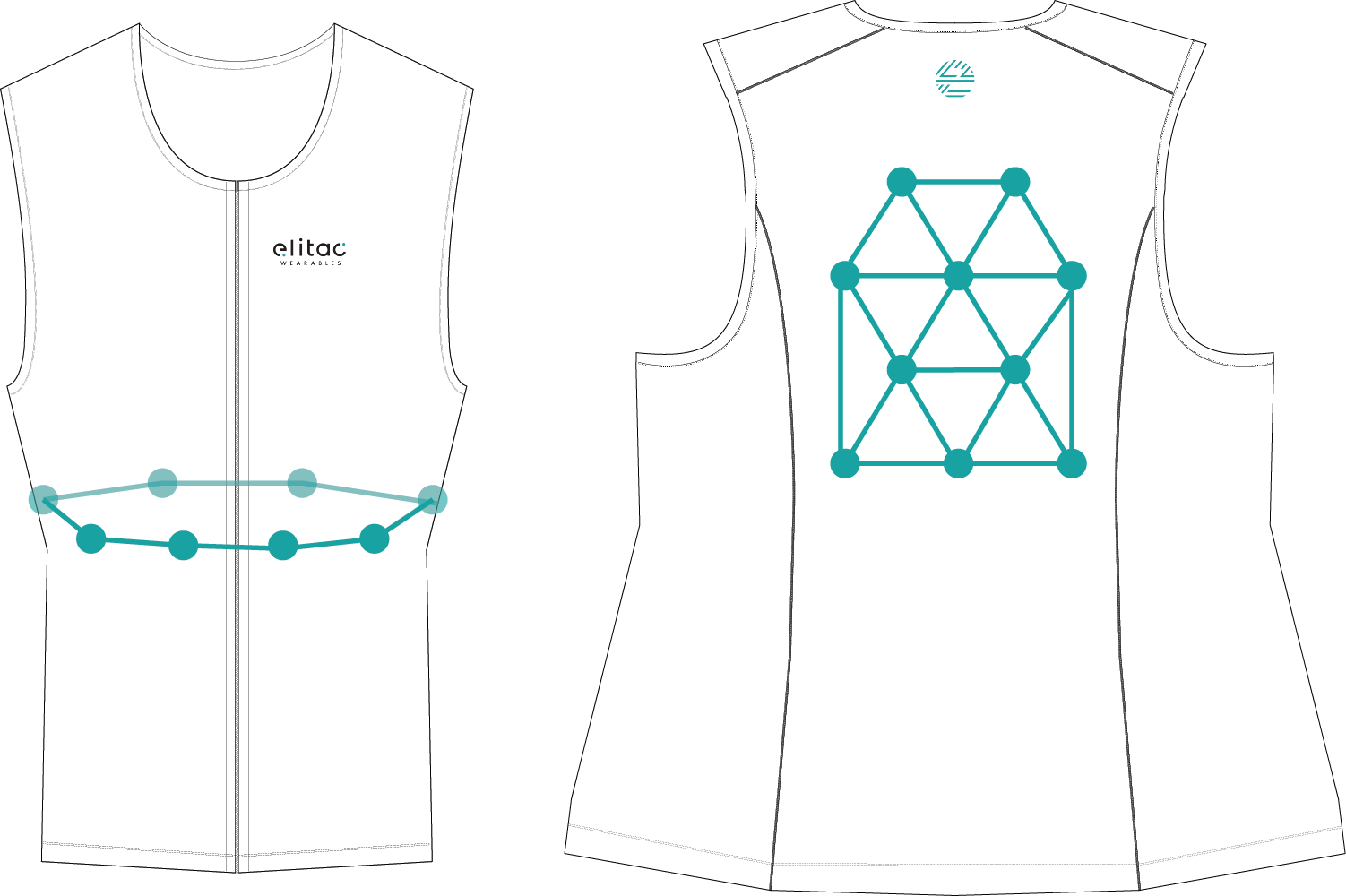

Our team has over 45 years of combined experience developing haptic feedback wearables. We’ve developed wearables for a variety of domains (Health, Medical, Safety and Sports), in various configurations (belts, vests, shirts, sleeves) and for a wide range of applications.

To ensure we achieve the most cost-effective haptic feedback implementation, we take the following factors into account:

Hardware, software & integration

Different vibration motors (tactors) have different applications. We have used and/or researched the most recent and effective options, helping us advise you on the best type and implementation for your wearable.

By balancing end user requirements, weight, cost, integration options, vibration strength, etc. we can help you develop the most efficient haptic feedback wearable. And thanks to our haptic feedback building blocks, we are able to quickly test and refine new applications.

To ensure our knowledge remains current and help you take advantage of the latest technological developments, we continually research new technology options in our Wearables Lab.

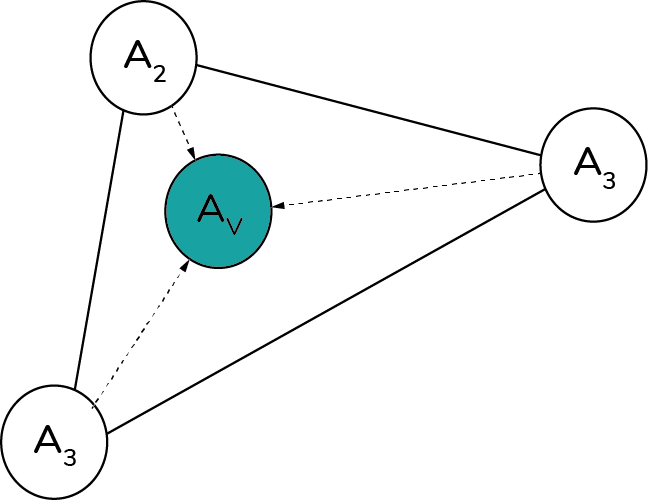

Haptic interpolation

We use haptic interpolation to develop wearables that are more efficient, lighter and cheaper to manufacture.

Haptic interpolation is a concept that allows us to generate haptic sensations anywhere on a patch of skin that is covered by a set of vibration motors – not only underneath or at the location of the vibration motor. In order words, we can generate the sense of vibration (Av) anywhere on the line of 2 or in the area of 3 actual tactors.

Learn more about haptic interpolation here.

Human factors & patterns

We use scientific research and our own experience to advise you on how to best communicate information to the user:

- How and where to position the vibration motors in the constellation (formation).

- Which patterns will be most intuitive and effective, for example, long or short strokes, taps, frequency, etc.

Interesting in learning more?

Contact us or consult these scholarly articles to learn more about haptic feedback technology:

- Van Erp, J. B. F., & Self, B. P. (2008). Tactile Displays for Orientation, Navigation and Communication in Air, Sea and Land Environments (Les systemes d’affichage tactiles pour l’orientation, la navigation (RTO-TR-HFM-122). http://oai.dtic.mil/oai/oai?verb=getRecord&metadataPrefix=html&identifier=ADA492500

- Escamilla-Nunez, R., Michelini, A., & Andrysek, J. (2020). Biofeedback Systems for Gait Rehabilitation of Individuals with Lower-Limb Amputation: A Systematic Review. Sensors, 20(6). https://doi.org/10.3390/s20061628

- Gilson, R. D., Redden, E. S., & Elliott, L. R. (2007). Remote tactile displays for future soldiers (ARL-SR-0152).

- Huisman, G. (2017). Social Touch Technology – Extending the reach of social touch through haptic technology [University of Twente]. https://doi.org/10.3990/1.9789036543095

- Israr, A., & Poupyrev, I. (2011, May). Tactile Brush : Drawing on Skin with a Tactile Grid Display. CHI 2011

Contact us

Contact us to find out how we can help you develop a wearable with efficient and cost-effective haptic feedback.