Wearable Development

Services

We can help you with a specific expertise,

Leverage our team's expertise and save time and costs in your wearable development!

Wearable Development

At Elitac Wearables, we have wearable development experience since 2012. We have developed products for the automotive, medical, safety, research, and sports sectors.

You might be new to the world of wearables, or already active and getting wearables in production for years, at some point, you might find yourself stuck in your development, or lacking certain expertise.

This is where our experienced team comes in!

Whether you are missing a specific expertise, or whether you want to outsource the full development, we provide full-service development services to help you out.

As part of this process, we offer wearable design validation to ensure that your product meets the required performance and reliability standards before production.

Our skills in wearable product development

Our multi-disciplinary team has all disciplines needed for wearable development in-house:

Our expertise in wearable development

Our team is specialised in cutting-edge wearable development, with expertise in:

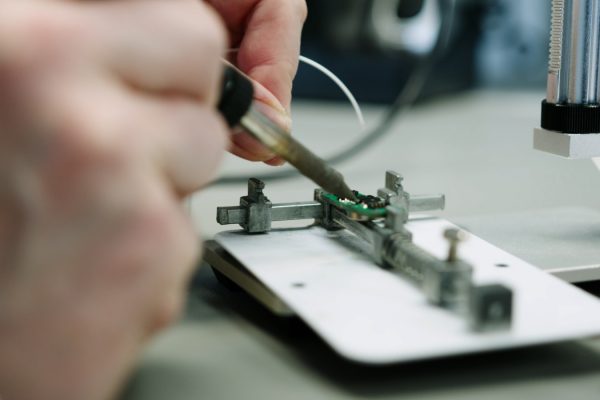

- Integration techniques (integrating electronics and textiles)

- Haptic feedback systems

- Softgoods & garment development

- Hardware and (embedded) software engineering

How we have already helped some of our clients

In more detail, here are some of the topics we have assisted our clients with:

- Electrode selection & integration (Johan Sports)

- Proof of Concept & Pilot Testing (Eldor Labs)

- Bug fixing before market launch (Danu Sports)

- Hardware mamagement and production (McRoberts)

Watch our company video to find out

what we can do for you!

Our wearable development process

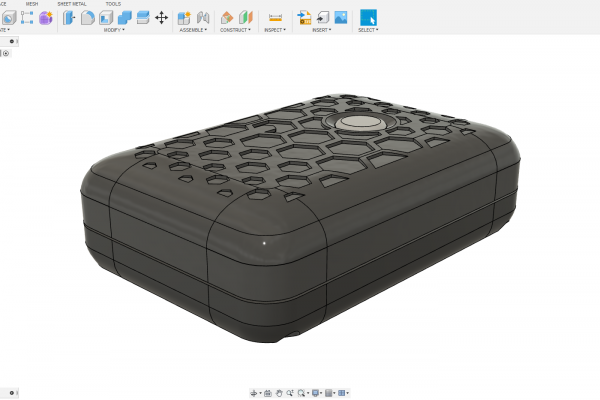

From idea to market-ready product, we support every step of the wearable development cycle, ensuring a smooth transition from concept to production. Whether it is turning an idea into a Proof of Concept to acquire funding, developing an existing Proof of Concept into a prototype for user testing and validation, or helping partners iron out the final wrinkles before scaling up production.

The Elitac Wearables development process is specifically designed to maximise predictability and minimise risk.

Find out more about our wearable solutions for the safety, health, and sports sectors here.

Why clients choose us as their wearable product development partner

Experience

We have developed several successful wearables for the safety, health and sports sectors. Even though the wearables we develop utilise the newest and experimental techniques and materials, our experience allows us to accurately plan the development process and deliverables. This minimises risk and upfront investments for our partners.

Research

Wearable technology improves continuously as a results of new scientific insights and the development of new materials. To ensure we are always up-to-date on the latest techniques, we invest significant time and resources in research. We partner with several universities, hospitals and research institutes from around the world to translate results from scientific research into practical applications.

Multi-disciplinary team

We have a multi-disciplinary internal development team consisting of hardware & software design for wearables, industrial and soft goods design, marketing and business development experts. We only rely on external parties for raw materials. The fact that each discipline is involved in every step of the development process means that the end result makes sense from all perspectives.

Building blocks

We have developed hardware and software building blocks that allow us to produce prototypes more cost-effectively and in shorter time frames. For example, we have several integration techniques ready for application and our proprietary/custom OS ‘TacOS’ allows for faster, cheaper and more compact wearable development.

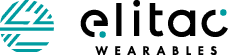

Wearables Lab

We have a 180m2 state-of-the-art Wearables Lab with all the equipment required to develop wearables. The entire product development cycle can be handled in-house: from idea to prototyping, to limited production (up to 100 pieces). For production at a larger scale, we have a reliable network of manufacturing partners.

Scrum

Our Scrum working method allows us to accurately predict progress and costs, while keeping a strong emphasis on the end user. It also means we can quickly identify and fix defects.

Contact us

Looking for a wearables development partner? Please hit the button below, leave your details in the form, and we will be in touch as soon as possible!