Today, our hardware team share some of the measures they take to minimise wearables development risk:

1. Define the wearable's main features and specifications: Are they feasible for the target cost price?

Based on the definition of your business case, you will have identified a target cost price. Before you start development, it is essential that you define the wearable’s main requirements. Then, check if it is possible to deliver all these features at a competitive cost price.

With technical advances in electronics miniaturisation and smart textiles, the possibilities for new wearables are seemingly endless. But if the components themselves already cost more than end users would be willing to spend, it is time to rethink your strategy.

Similarly, keep in mind the development time (and cost) required to achieve the desired functionality, portability, longevity and accessibility. This will go a long way toward minimising wearables development risk from a hardware perspective.

2. Identify risks and level of certification at an early stage

This will help you eliminate or identify certain design routes. For example, EMC (Electromagnetic Compatibility) regulations vary greatly depending on the type of end user. Is the wearable destined for the military, a consumer, or is it an industrial or medical device? Each use case carries with it different regulations. Adhering to these regulations makes certain hardware or design choices problematic, expensive or even impossible.

Similarly, medical devices must undergo conformity tests that demonstrate they are safe and will perform as intended. And this is only one of the possible certifications required to bring your wearable to the market successfully. Having a clear idea of the required certifications will help you identify the best route at an early stage of the development. And goes a long way toward lowering development risks.

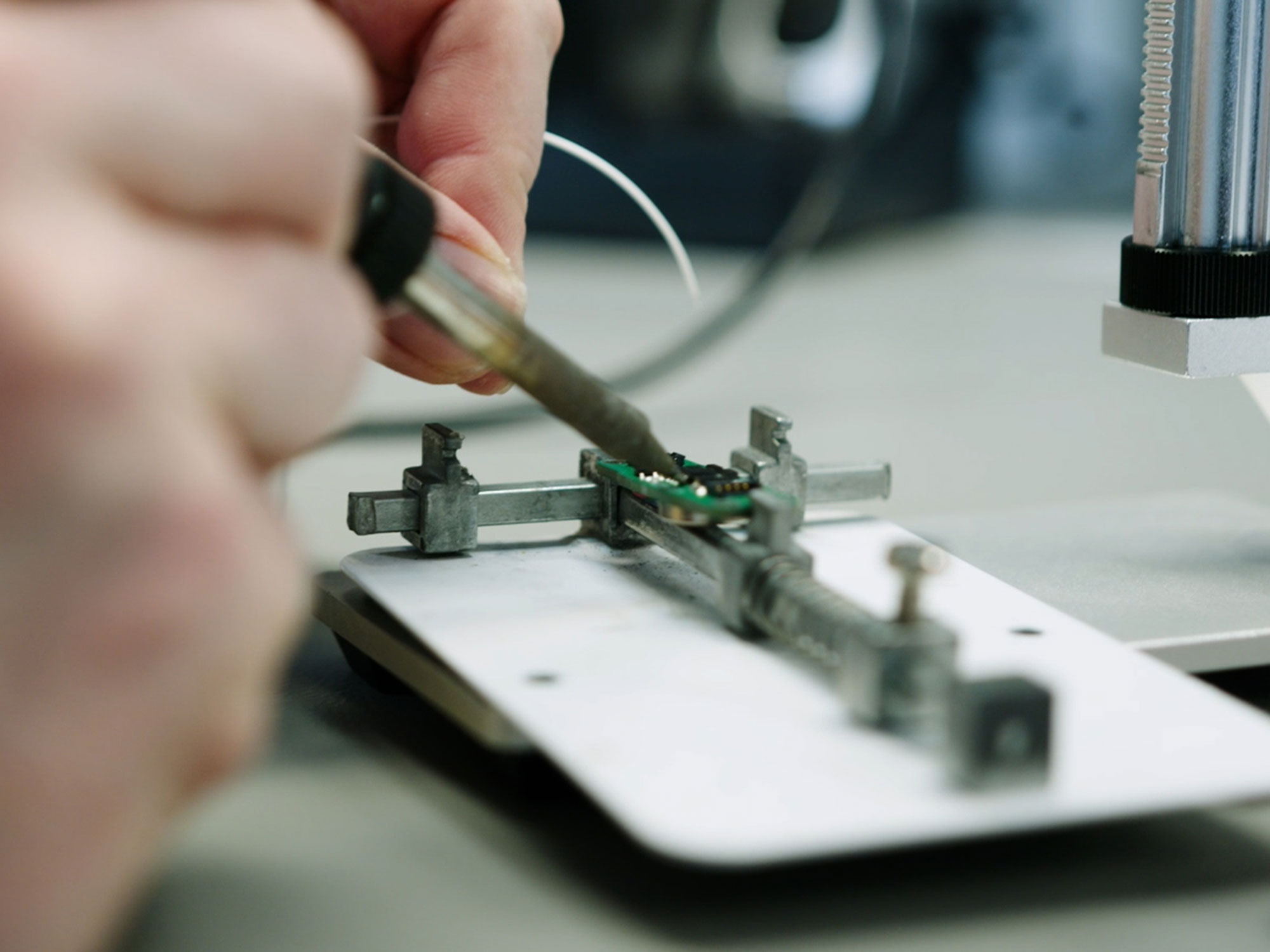

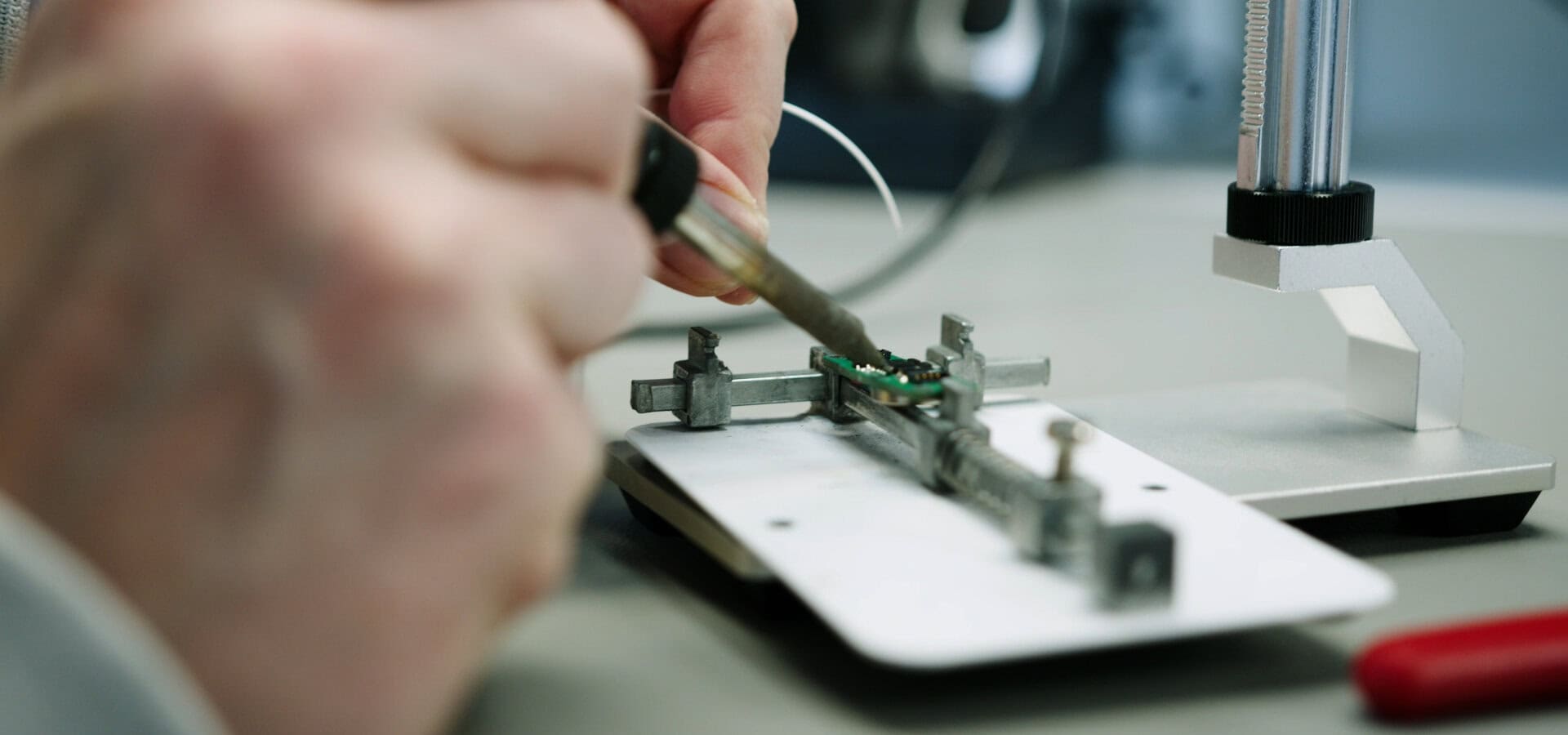

3. Use existing hardware building blocks

Wherever possible, re-use hardware solutions that have already demonstrated their worth: There is no need to reinvent the wheel every time.

For example, at Elitac Wearables, we have developed haptic feedback hardware (vibration motors and a PCB) that has been tested thoroughly, both in the lab and in the field. It has proven to be flexible, sensitive, durable and effective.

When we start a new development project, we make use of these proven building blocks to minimise risk and development time. If that’s not an option for you, don’t hesitate to do your research and examine wearables that are already on the market. What can you learn from them in terms of hardware choices, design, etc.?

But: make sure you also keep an eye out for new technological advances. Our field moves fast. New solutions are being developed continuously, so it pays to stay up to date.